As part of an NWO-supported public-private collaboration, measurement equipment specialists Bronkhorst and Krohne teamed up with the technical universities of Delft and Twente to bring flow meters into the next generation. Their goal: to develop new and innovative meters that could provide real-time insight and analytics of flowing media, all without having to interrupt the flow.

Author: Collin Arocho, Bits&Chips

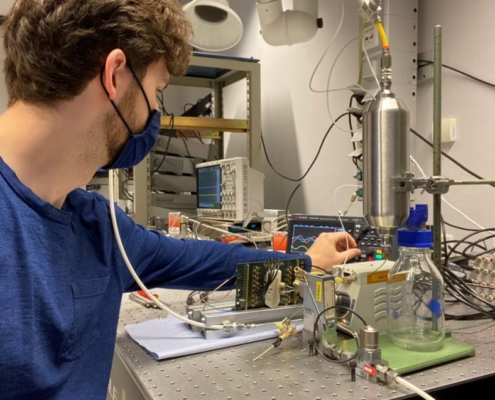

Lead picture: An ultrasonic flow meter installed on a customer setup. Credit: Bronkhorst

All types of industries are working to find ways to collect data and use analytics to get the most out of their products. According to the experts at Bronkhorst High-Tech and Krohne Altometer, the flow measurement market is inevitably trending in the same direction. “We want to be able to measure more than just the flow of media through a pipe. We want to measure the flow plus other parameters like density, viscosity and other meaningful quantities,” explains Joost Lötters, science officer at Bronkhorst.

In industry, Lötters has spent more than two decades focused on developing mass flow meters used in measuring and controlling the flow of liquid and gas for a variety of applications in laboratory, machinery, industrial and hazardous areas. Next to this “day job” at Bronkhorst, he serves as a part-time professor of microfluidic handling systems at the technical universities (TUs) in both Delft and Twente. Meaning that when it comes to knowledge of the measurement equipment market, he has a firm grasp on customer demands, as well as the technological innovations that are needed in the domain.

In 2014, Lötters caught wind of the partnership research incentive program through the Dutch Research Council (NWO), where the council would match funds, from 3-10 million euros, to support public-private collaboration projects. With inside knowledge of the research capabilities at the TUs, he reached out to his colleagues at Krohne to help guide the development process of next-generation flow meters in a program called “Flow+” – aimed at collecting and harnessing valuable data to give customers more insight and to bring down costs.

Researchers were invited to submit proposals of how their idea would fit in the program. “We looked at the proposals through the lens of NASA’s technology readiness levels,” describes André Boer, Krohne’s general manager. “Typically, universities work up to level 3 or 4, the stage of a proof-of-concept or functional model. For Flow+, we wanted something more advanced: we wanted to go to TRL 6, a fully functional and transportable model, with the ambition to take it all the way to level 9 – mission success. We wanted to use our expertise to help the researchers bridge the gap and to get first-hand experience from industry, but also to get our products to the market.”

Ultrasonic

In all, collaborators received a total of 18 submissions of project designs. Four proposals made the final cut. Now, a few years later, two of the projects have already matured to TRL 5. The first of them is an ultrasonic flow meter, stemming from TU Delft. By clamping on this small device to a pipe, the system uses soundwaves to penetrate and measure the flow inside, collecting valuable information such as the pipe diameter, wall thickness and speed of the liquid.

“To do this requires a very intelligent system that can calibrate itself automatically in any setting,” depicts Jankees Hogendoorn, general manager of Krohne’s New Technologies Group. “In this setup, the system utilizes a phased array of transducers – a group of sensors – to steer the acoustic beam to specific points and specific planes to gather information from an entire cross-section of the pipe. This allows us to collect valuable data and determine flow velocity from point to point without the need to cut into the pipe.” Meaning end-users not only receive more accurate analytical data than ever before but can monitor the health and stability of pipelines while realizing faster installation with minimal risk of leaks and a reduction of the total cost.

“I’ve been working at Krohne for 35 years, and we started developing ultrasonic flow meters really early on, as this was one of our biggest wishes,” expresses general manager Boer. “While the ideas were there, when it came to actually producing such a tool – forget it. The technology being developed by TU Delft just didn’t exist 20 or 30 years ago. That’s one reason this collaboration with the TUs has been such a success in our eyes. Through this program, we’ve been able to make use of the latest developments and realize next-gen technology.”

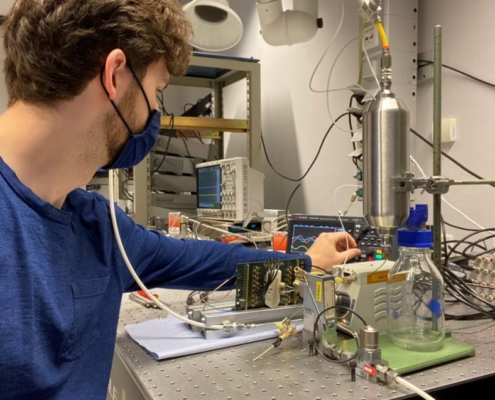

Flow+ PhD student working on the micro Coriolis flow sensor in the lab at the UT. Credit: Flow+

Coriolis

The second of the most advanced projects is the thermal noise limited Coriolis flow meter, a collaboration between the TUs of Delft and Twente. A Coriolis-type flow sensor consists of a vibrating tube through which a fluid is flowing. The moving mass of the fluid results in Coriolis forces acting on the vibrating tube that can be detected and used to determine how much substance is passing per second. However, when measuring gasses, it can be a little tricky because of their low density – implying a lot of pressure is needed to push the gas flow through the pipe.

“By creating an inline solution, we can collect all the relevant data and ensure that the high-throughput processes can be controlled and adjusted in real time, thus, limiting downtime of the system,” explains Lötters. “At Bronkhorst, we specialize in using the Coriolis principle for ultra-low liquid flow rates and we would like to improve this principle for measuring gas flows. But to do that, we need to dramatically improve the signal-to-noise ratio of the device, since the mass flows for gases are much lower than those for liquids due to their lower densities.”

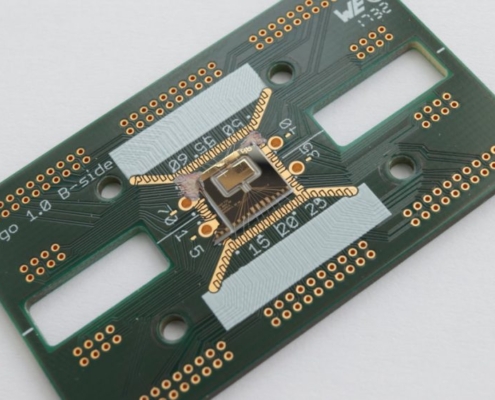

To find a solution, Twente assumed the role of improving the sensitivity of the sensors to measure lower flows. Meanwhile, Delft took to upgrading the electronics used to decrease the noise level. After a few iterations of in-house development, this team is close to achieving a custom ASIC chip that will be integrated with the enhanced sensor from Twente en route to a market-viable product.

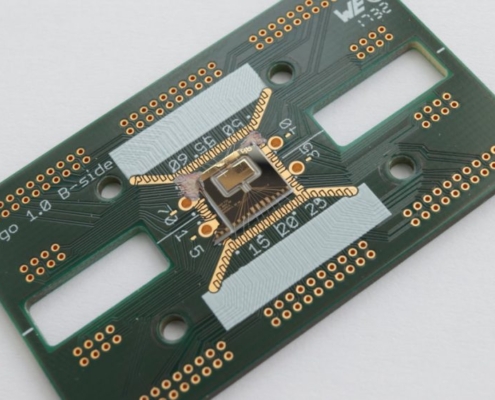

Printed circuit board with the micro Coriolis flow sensor chip mounted in the middle. Credit: Flow+

Plus

“The proof of the pudding is in the eating, so we still have to see how it all integrates, but I would call this cooperative effort a success,” says Lötters. “There are still some questions we’re addressing as we advance through the technology readiness levels. But our vision of measuring ‘flow plus something else’ is being realized. Now, we measure flow. Next, we’ll measure flow plus quantities such as density, viscosity and heat capacity. Finally, we’ll go towards recognition of gases, liquids, and determination of the composition of gas and liquid mixtures, for example by adding a machine-learning component. It’s a step-by-step process, but that’s the direction we’re going.”

In terms of future application of the Flow+ solutions, the market possibilities are quite diverse. “Applications of these systems range from medical solutions like measuring the composition of medicine mixtures of multi-infusion setups in hospitals and nutrition supply and waste drainage in organ-on-a-chip systems to energy content measurement in mixtures of fuel gases or research on catalysts and recipes for effectively extracting oil from wells in the oil and gas industry and many others,” illustrates Lötters. “All of these industries rely on the monitoring and measurement of both the flow in a pipeline and the content of the flowing media.”

Flow+

For the Flow+ project, measurement equipment specialists Bronkhorst High-Tech and Krohne Altometer teamed up with Delft University of Technology and the University of Twente to develop next-generation flow meters with enhanced data collection capabilities and increased sensitivity. The project is co-funded by Holland High Tech, Top Sector HTSM, and the Dutch Research Council (NWO), with a public-private partnership grant for research and innovation.

Article via Holland High Tech news